Design History

I have worked on numerous projects throughout my career, here are a few examples:

Self Contained Rugged Design Test System Entitled "minFLITS"

This consisted of a rugged laptop fitted with an underneath instrument bay. The instrument bay allowed up to four PMC (PCI mezzanine card) instrument / measurement modules to be fitted within a rugged temperature-controlled environment.

I was responsible for the complete hardware design of this instrument bay except for the mechanical case. That is the electronic intelligent PCI backplane and all hardware interfaces between the laptop, instruments and the outside world. The resource backplane even allowed for "Hot" switching of the PMC instruments to conserve power and limit unnecessary heating when they were not in use.

A full description of this product can be found at miniFLITS

Digital Multimeter

This full featured module was designed on a PMC format to be fitted within the instrument bay of the miniFLITS described above.

The PMC Cardmodule contained an onboard intelligent 16bit ADC with built in filtering. It could measure voltages up to 100 volts (DC and True RMS) and resistances to 100 Megohms with ranges and accuracy comparable to the National Instruments NI4050 PCMCIA card.

This module with its size and low power consumption is ideal for portable measurements and data logging on laptop computers.

I wrote the full test and evaluation software in VB6. This product was developed on a tight timescale and I achieved conception to working prototype in three months. The idea and design architecture were again all my own.

Interface to the Flight Control Computer on a Lynx Helicopter

I designed the electronic interface between this Flight Control Computer and the miniFLITS Instruments. The interface consisted of relays, solid state multiplexers, buffers and signal conditioning electronics. It also contained a phase lock loop to enabled precise phase, frequency and amplitude control of the AC stimulus signals.

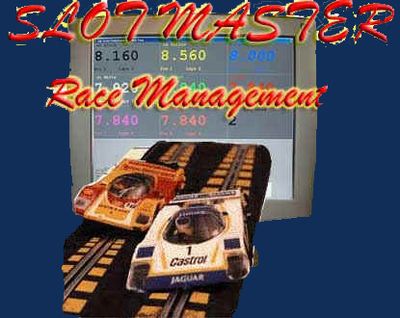

Slot Master Race Management System

The Slot Master is a race management system designed to control and time scalextric and other slot car events. Its unique features are that it uses either a USB or PCI port and therefore is fully compatible with modern PC's and laptops.

Besides normal lap counting and timing to 1/1000 second it is able to measure the throttle voltage for use in instant false start detection, fuel management and performance graphs. I pioneered some unique features with this software that have only recently just been copied.

The windows software was written in VB6 and the firmware for the USB interface was written in C.

This system was fully conceived and designed by myself and I have sold over 160 systems worldwide.

A full description of this product can be found at Slotmaster

Distributed Backplane and Cable Harness Test System

This test system was conceived by myself and provides a unique way of interfacing to multipoint test targets such as backplanes.

The test system consists of high pin count intelligent test cards distributed around the target and connected by a 14way daisy chain ribbon cable. This avoids large and unmanageable cable looms that are very prone to damage. Again, this system is very innovative with only one other of its kind sold in the world.

A full description of this product can be found at Terotest

High Voltage Cable Harness Test System

I was a former director of DTR Systems that designed and manufactured these testers. Although I have now sold the company, I am still closely involved and continue to provide a full design and support service.

I was solely responsible for the full hardware and system design of this product family with the software written by another company director. The system is capable of measuring Gig ohm resistances at 1000 Volts down to milliohm values at 1 Amp.

The tester also supports some unique functional features such as remote control of vibration and environmental chambers. These testers have been sold into some major blue-chip companies such as BAE, IBM, Goodrich and just recently Rolls Royce.

More information on this product can be found at DTR Systems.

Torque Measurement System

Design, development and product introduction of a standalone torque measurement system used by the MOD to measure engine performance on a Lynx helicopter. The product was a standalone microprocessor-based system with its own display. All aspects of the product were designed by myself except for the firmware.

Gas Detection

I designed an eight-channel gas detection system for the gas division of Blakell Ltd. I was responsible for the system, electronic and firmware aspects of this product with only the PC windows software written by someone else. The microprocessor-based system could be used as a standalone detection product, with its own alarms and warnings, or linked to a PC for data logging and remote control.

Schlumberger/ Factron Series 7700 Test Systems

I led a small team of people to design and develop the in-circuit capability on this platform of testers. The tester was extremely successful and achieved many sales back in the 1980's.

The following is a link to a patent I hold on the digital in-circuit architecture for these systems.

Copyright © 2020 Electronic Design No - All Rights Reserved.